struggle to consistently meet regulatory limits for BOD, COD, and TSS, risking hefty fines and operational shutdowns? If your facility is grappling with these challenges, you’re not alone—and there are proven methods for transforming compliance headaches into operational wins

A Startling Look: Why TSS COD BOD Reduction Is Crucial for Wastewater Compliance

For every site manager, plant supervisor, or EHS specialist, failing to contain BOD, COD, and TSS levels is more than a paperwork hassle—it’s a financial and reputational risk. Regulatory agencies enforce strict discharge limits on biochemical oxygen demand (BOD), chemical oxygen demand (COD), and total suspended solids (TSS) because high concentrations can devastate aquatic environments and public health. Noncompliance can lead to costly penalties or even force plants offline until remedial actions are taken.

Achieving tss cod bod reduction isn’t just about ticking boxes for regulators; it ensures operational efficiency, extends equipment life, and builds community trust. Today, water treatment plants must proactively monitor bod levels, optimize the treatment process, and implement adaptive solutions to stay ahead of rising influent variability and changing regulations. Immediate, practical steps—rooted in science and real-world experience—offer the most sustainable path toward wastewater compliance and environmental stewardship.

What You'll Learn: Master TSS COD BOD Reduction in Wastewater Processes

- Industry-standard techniques for tss cod bod reduction

- How to assess and optimize wastewater treatment systems

- The science behind tss removal and BOD in wastewater

- Key equipment and best practices for regulatory compliance

- Red flags and troubleshooting in real-world water treatment scenarios

Understanding TSS, COD, BOD in Wastewater: Definitions and Impacts

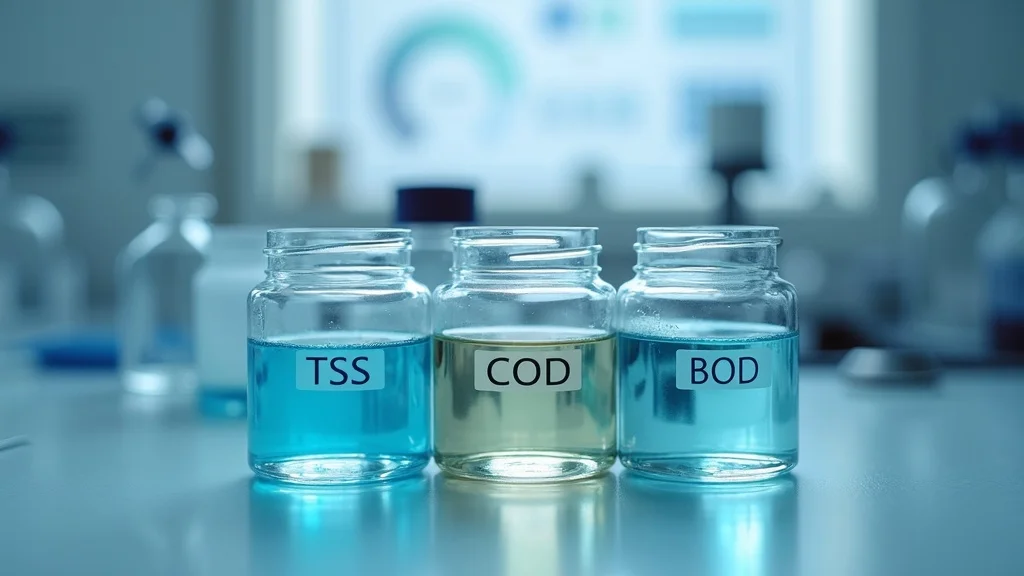

Finding the right strategy starts with a clear grasp of the parameters in play. BOD in wastewater reflects how much oxygen bacteria will consume breaking down organic matter. TSS removal targets visible particles suspended throughout the water, while COD includes both organic and some inorganic contaminants that draw on oxygen resources. Each has distinct regulatory limits and operational implications, with high bod, high cod, and excess suspended solids often signaling deeper process inefficiencies or upstream issues.

Poor control of these factors directly affects oxygen demand across receiving waters, leading to depleted fish stocks, toxic buildups, and even plant crises like bulking, plugging, or permit violations. A robust monitoring and control approach ensures you’re not just avoiding fines but creating cleaner, more sustainable water for everyone downstream.

What Is BOD in Wastewater and Why Is It Monitored?

Biochemical oxygen demand (BOD) measures how much dissolved oxygen is consumed by microorganisms while decomposing organic matter over a specific period (usually five days, BOD5). Plants monitor bod in wastewater to gauge the pollution load and the efficiency of biological treatment stages. High bod levels indicate excess organic pollution, which can smother aquatic life if not sufficiently treated. Accurate BOD testing guides both equipment sizing and regulatory reporting, ensuring timely action to reduce bod and achieve long-term compliance.

TSS Removal and Its Role in Wastewater Treatment

Total suspended solids (TSS) refer to all particulate matter—organics and inorganics—that remain suspended in water after primary physical treatment. Successful tss removal prevents downstream clogging, supports biological process health, and satisfies permit obligations. Effective TSS control relies on mechanical screens, sedimentation, and sometimes enhanced treatments such as coagulation, all of which require routine maintenance and process adjustment as influent conditions change.

Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD): Key Differences

While both COD and BOD are proxies for the polluting potential of wastewater, they measure different things: BOD focuses on biodegradable organic matter, while chemical oxygen demand (COD) measures all substances that can be chemically oxidized. COD tests are faster, detecting both biodegradable and non-biodegradable pollutants. Comparing BOD and COD helps identify the fraction of organic content amenable to biological treatment, guiding process design for optimal cod reduction and sustainable effluent quality.

| Parameter | Definition | Measurement Method | Common Regulatory Limits |

|---|---|---|---|

| BOD (Biochemical Oxygen Demand) | Amount of oxygen needed by bacteria to break down organic matter in water | BOD5 Test—Incubation for 5 days | <30 mg/L (typical municipal outfall) |

| COD (Chemical Oxygen Demand) | Total oxygen required to oxidize all organic (and some inorganic) matter chemically | Potassium dichromate digestion, spectrophotometry | <125 mg/L (typical municipal outfall) |

| TSS (Total Suspended Solids) | All particles suspended (not dissolved) in water | Gravimetric analysis after filtration | <30 mg/L (typical municipal outfall) |

Sources and Challenges of High BOD, COD, and TSS Levels

Many industrial and municipal treatment plants face persistent high bod, cod, and tss levels due to variable influent composition or seasonal upsets. Common sources include food processors, dairies, slaughterhouses, pulp and paper mills, and stormwater run-off—each of which may introduce large amounts of organic matter or suspended solids into the treatment plant.

Uncontrolled pollutant loads can overwhelm biological and chemical processes, cause high oxygen demand, and lead to regulatory consequences such as permit violations, fines, or mandatory facility upgrades. Frequent review and re-optimization of the wastewater treatment plan are required to address these risks.

- Common sources of high BOD in wastewater

- Industrial contributors to elevated TSS and COD

- Regulatory consequences of high bod levels and suspended solids

How to Reduce BOD and TSS in Wastewater: A Step-by-Step Approach

"Effective tss cod bod reduction begins with a detailed process assessment—every plant has unique variables. – Industry Wastewater Specialist"

Reducing BOD and TSS effectively starts with a holistic understanding of your plant’s influent, process bottlenecks, and compliance targets. The first step is rigorous monitoring—collecting representative water samples, measuring bod level, tss, and cod, and analyzing historical data for trends.

Next, you should review existing treatment processes: primary screening and sedimentation for basic removal, followed by chemical and biological systems tailored to influent characteristics. Adjusting parameters such as chemical dose, sludge age, and oxygen supply can often lower bod and improve effluent quality—without large capital costs. Ongoing staff training and equipment maintenance are critical for consistent, robust results in your wastewater treatment plant.

For a deeper dive into how these process adjustments and monitoring strategies can be tailored to your facility, explore the comprehensive solutions and technical expertise available at CSI Environmental Inc. Their resources can help you address specific challenges in TSS, COD, and BOD reduction with proven, real-world approaches.

Primary Methods: Physical, Chemical, and Biological Treatments

- Primary treatment: Screening and sedimentation

- Physical separation for total suspended solids

- Chemical precipitation to reduce COD

- Biological processes for BOD and COD removal

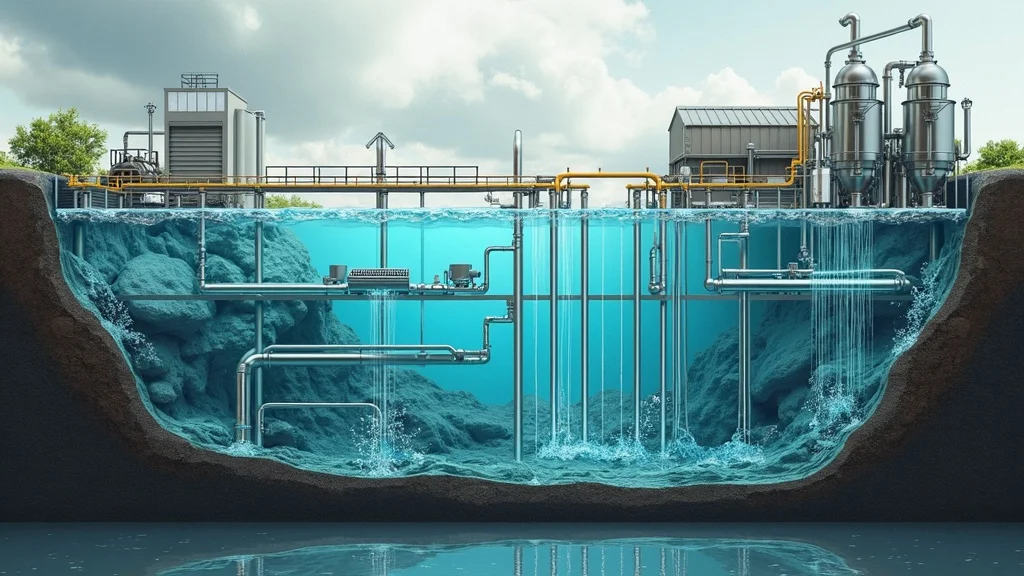

The primary treatment stage removes coarse debris and dense solids via mechanical screening and sedimentation, which can eliminate a significant portion of total suspended solids. Follow-up physical methods like dissolved air flotation or sand filtration provide further tss removal, especially for fine particulates. Chemical oxygen demand is reduced using coagulants and flocculants that bind soluble and colloidal material, allowing for more efficient separation. Finally, biological reactors such as activated sludge or fixed film reactor systems target remaining organic matter, lowering bod and cod through microbial activity.

The Activated Sludge Process for TSS COD BOD Reduction

The activated sludge process is the backbone of most modern wastewater treatment plants, providing powerful removal of bod in wastewater and tss. Air is pumped into aeration tanks, stimulating microbial populations to consume organic pollutants. The process relies on careful control of sludge age (the residence time for biological solids), oxygen level, and loading rate (inflow volume and pollutant strength). Optimized operation results in stable effluent, high removal rates, and lower sludge disposal costs.

Problems such as bulking, foaming, or poor settleability can often be traced to changes in influent composition, process imbalances, or insufficient oxygen supply. Regular performance review and prompt adjustment are crucial to keep your system at peak efficiency and compliance.

Role of EQ Tank and Pre-Treatment in Controlling BOD, COD, and TSS

Equalization (EQ) tanks serve as hydraulic buffers, evening out fluctuating flow rates and pollutant loads before biological or chemical treatment. By dampening peaks in high bod, tss, and cod, EQ tanks enable more stable operation and optimum performance of downstream processes. Pre-treatment—such as grit removal or pH correction—further protects equipment and increases process reliability. Plants with advanced EQ and pre-treatment routinely achieve better cod reduction and tss removal, even in industries with highly variable influent.

Optimizing Activated Sludge and Sludge Processes for Lower BOD and COD Levels

Optimization means getting more from your existing assets. This involves continuous review of sludge process control (especially sludge age and return rates), enhanced aeration strategies, and fine-tuning the loading rate to match system capacity. Real-time monitoring technology can help identify small changes in bod levels and cod that, if left unchecked, may lead to compliance issues.

A proactive approach—combining routine sampling, automated feedback loops, and regular process audits—ensures persistent lower bod and cost-effective operation for years to come.

Key Process Parameters: How Sludge Age, Oxygen Supply, and Loading Impact Results

Fine control of critical process parameters—such as sludge age, dissolved oxygen supply, and organic loading rate—allows for real-time adaptation to changing influent. Sludge age determines which microbes dominate the ecosystem, affecting both removal efficiency and sludge characteristics. Sufficient oxygen is absolutely vital; too little and biological performance crashes, too much and you waste energy. Effective loading management keeps reactors from overloading or starving, ensuring reliable treatment and minimal downtime.

Troubleshooting: Common Problems in TSS, COD, and BOD Reduction

Even the best-designed plant faces upsets: sudden bod or cod spikes, bulking sludge, or equipment failure. Common red flags include rising effluent solids, oxygen depletion, and foaming. Most causes relate to influent variability, insufficient pre-treatment, or operator error. Rapid identification and targeted action—such as chemical adjustments, equipment calibration, or process rebalancing—are vital for quickly restoring compliance.

Continuous operator training, preventative maintenance, and real-time monitoring tools have become industry best practices for minimizing downtime and maintaining robust reduction across all parameters in the wastewater treatment process.

Technology Highlights: Advanced Water Treatment Solutions for TSS COD BOD Reduction

Emerging technologies continue to push the boundaries of tss cod bod reduction, offering new solutions for stubborn pollutants or tight compliance deadlines. These include advanced filtration, membrane systems, and fully integrated wastewater treatment plants that combine multiple unit processes for maximum efficiency.

Investing in these technologies can offer fast payback through improved effluent quality, energy savings, and long-term operational resilience.

Membrane Filtration and Total Suspended Solids Removal

High-tech membrane filtration systems—such as ultrafiltration (UF) and membrane bioreactors (MBR)—are increasingly popular in modern treatment plants. These systems achieve tss removal down to the sub-micron scale, supporting biological reactors with minimal maintainance downtime. They’re especially valuable for facilities dealing with high-strength influent or needing to reliably meet the most stringent discharge permits. Integrated controls and automated cleaning cycles make these a best-in-class solution for consistent effluent quality.

Integrated Wastewater Treatment Plants: Case Studies

Integrated treatment plants combine technologies—typically EQ, primary clarification, advanced sludge processes, and tertiary filtration—to achieve superior, reliable tss cod bod reduction. Real-world case studies show that targeted retrofitting or process adjustments can often lower bod and cod by up to 20% without major capital investment. Continuous process monitoring, staff training, and rapid troubleshooting lead to sustained compliance and major cost savings.

"Our compliance assessment routinely uncovers opportunities to lower BOD and COD by 20% or more without major capital investment."Short explainer video demonstrating the top 5 most effective treatment methods for TSS, COD, and BOD reduction in industrial wastewater, with visual transitions from raw influent to clean effluent, including animated infographics and real plant footage.

People Also Ask: How to Reduce BOD and TSS in Wastewater?

Practical Steps for Reducing BOD and TSS in Wastewater Treatment

To effectively reduce BOD and TSS in wastewater, start by optimizing physical removal methods (screening and sedimentation), which take out large solids. Follow up with robust biological and chemical steps—such as the activated sludge process or advanced filtration—to target dissolved and colloidal material causing high bod in wastewater. Always monitor eq tank performance, review all maintenance logs, and train staff regularly. Record changes in effluent via frequent water sample testing, and use findings to continually tweak the treatment plan for better results.

People Also Ask: What is the Relationship Between TSS and BOD?

Understanding Links Between Suspended Solids and Biochemical Oxygen Demand

There’s a strong, direct relationship between tss and bod in wastewater. Suspended solids often include organic debris that directly increases biochemical oxygen demand because bacteria break down both dissolved and suspended organics, consuming oxygen. Effective tss removal at the outset lowers the overall bod burden on biological reactors, simplifies process control, and minimizes the risk of regulatory exceedances. Routine monitoring and integrated process management tie these parameters together for maximum system reliability.

People Also Ask: Does TSS Affect COD?

How Total Suspended Solids Impact Chemical Oxygen Demand

Suspended solids often harbor both biodegradable and non-biodegradable substances that contribute to the overall chemical oxygen demand (COD). High tss can result in elevated cod readings, especially if industrial influent introduces stubborn contaminants or recalcitrant organics. Improving tss removal early in the treatment process ensures more accurate cod monitoring and easier permit compliance across all stages.

People Also Ask: Is BOD Part of TSS?

Clarifying the Distinction: BOD vs. TSS in Wastewater Analysis

BOD and TSS are closely linked but represent different aspects of wastewater pollution. TSS encompasses both organic and inorganic particles that remain suspended after basic separation, while bod in wastewater reflects only the oxygen-consuming potential of biodegradable organic content. Some BOD is always tied up in suspended (as well as dissolved) matter; hence, comprehensive monitoring and targeted treatment ensure compliance across both fronts.

Lists: Best Practices and Maintenance Tips for Ongoing TSS COD BOD Reduction

- Regular monitoring of bod level, tss, and cod

- Scheduled maintenance of treatment equipment

- Staff training on wastewater treatment procedures

- Implementation of process control systems

- Documentation and review of compliance records

FAQs: TSS COD BOD Reduction and Water Treatment

-

What is the normal range for BOD in wastewater?

Most municipal wastewater plants target BOD levels below 30 mg/L for treated effluent, although stricter permits may require even lower concentrations. Consistent BOD monitoring and process adjustment are essential to meet evolving regulatory requirements. -

How frequently should TSS and COD be monitored?

Daily monitoring of TSS and COD is standard for large plants, while smaller facilities may check these parameters several times per week. Increased frequency is recommended during process changes, seasonal shifts, or when troubleshooting high effluent concentrations. -

What are quick wins for lowering COD in tight timeframes?

Implementing chemical precipitation and optimizing existing coagulation processes offer rapid reductions in COD. Batching high-strength waste or increasing return rates in the sludge process can deliver quick compliance improvements. -

Which technologies are best for high-strength influent?

Membrane bioreactors (MBR), moving bed biofilm reactors (MBBR), and advanced oxidation processes excel at handling high-strength wastewater with persistent bod and tss loads. These technologies boost removal efficiency while maintaining robust plant performance.

Key Takeaways: Achieving Effective TSS COD BOD Reduction

- Comprehensive tss cod bod reduction protects your facility from violations

- A multi-step process is key to successful wastewater treatment

- Regular assessments enable ongoing compliance and optimization

Conclusion: Next Steps Toward Reliable TSS COD BOD Reduction at Your Plant

Consistent, compliant tss cod bod reduction requires a holistic approach—state-of-the-art technology, skilled operation, and continuous improvement. Start with a detailed assessment and unlock better results for your plant and community.

Get Our Free Evaluation - CALL US (626)-332-2500 - EMAIL US info@csi-environmental.net

Get Your Wastewater & Sewage Treatment Plants – Contact us today for a compliance assessment!

If you’re ready to take your facility’s performance to the next level, consider exploring the full range of environmental engineering and compliance services offered by CSI Environmental Inc. Their expertise spans not only advanced wastewater treatment but also integrated solutions for air, soil, and water quality challenges. By partnering with a team that understands both the technical and regulatory landscape, you can future-proof your operations and achieve sustainable compliance. Discover how a strategic approach to environmental management can unlock new efficiencies and long-term value for your organization.

Sources

- EPA – Wastewater Discharge Permits

- WaterOnline – BOD, COD and Toxicity: Parameters Key to Treatment

- Environmental Science.org – Wastewater Treatment

- Water Treatment Plants – What is TSS, COD, BOD in Wastewater?

- ResearchGate – Technical Summary of Activated Sludge Process

To enhance your understanding of effective wastewater treatment strategies, consider exploring the following resources:

-

“10 Tips for Reducing BOD and TSS in Water Treatment Systems”: This article provides practical advice on optimizing wastewater treatment processes, including the use of mechanical screens, equalization tanks, and pH control to effectively reduce BOD and TSS levels. (hohwatertechnology.com)

-

“BOD and TSS Removal”: This resource discusses various treatment technologies, such as biological systems, membranes, and tertiary processes, that can achieve significant reductions in BOD and TSS, ensuring compliance with stringent effluent requirements. (aqua-aerobic.com)

By delving into these materials, you’ll gain valuable insights into optimizing your wastewater treatment operations for improved compliance and efficiency.

Add Row

Add Row  Add

Add

Write A Comment