Did you know that over 1 billion gallons of wastewater are processed each week in Riverside County? This staggering figure is more than just a statistic—it’s a powerful reminder of just how critical industrial waste water treatment Riverside is to every resident’s health and to our shared environment. Industrial processes generate a complex blend of contaminants, but with advanced treatment plant technology and rigorous oversight, Riverside is working tirelessly to ensure the water that returns to our rivers and neighborhoods is safe and clean. In this article, you’ll learn how modern treatment systems, strategic control programs, and community involvement can protect the region’s most precious resource—our water.

Industrial Waste Water Treatment Riverside: Why Urgent Action Is Critical for Water Quality

Riverside County faces immense pressure from its growing industrial and commercial sectors, each contributing to the complexity of its wastewater management needs. Immediate action in industrial waste water treatment Riverside is not just a regulatory checkbox but a pivotal step toward preserving water quality for both present and future generations. Without prompt and effective treatment, pollutants from manufacturing and other industrial activities can seep into the local sewer system, threatening the integrity of drinking water sources and local ecosystems. For every million gallons per day processed at a treatment plant, hundreds of thousands of lives are shielded from hazardous chemicals and biological contaminants.

Beyond environmental concerns, untreated industrial wastewater brings economic and social risks to the entire community. Regulatory bodies like the regional wastewater authority enforce measures to act to regulate pollution, but timely compliance remains key. Delays or negligence can result in costly cleanups, financial penalties, and even harm to Riverside’s image as an environmentally responsible region. That’s why local agencies, industry leaders, and residents must rally to ensure these critical processes aren't just upheld—they're continually improved.

How industrial waste water treatment Riverside impacts local water quality and community health

Essential processes and modern solutions for water treatment and treatment plants in Riverside County

Key regulations and the importance of regional wastewater authority oversight

Steps you can take to help preserve clean water in Western Riverside

Protecting Water Quality: Industrial Waste Water Treatment Riverside Impact on the Region

Clean water in Riverside County isn’t just a luxury—it’s a necessity that fuels daily life, economic growth, and environmental sustainability. Industrial waste water treatment Riverside operations play an outsized role in preventing widespread contamination, and their effectiveness has direct consequences for every business and household in the region. The reliance on imported water for some parts of the county only amplifies the urgency: every drop reclaimed through modern treatment plants means less dependence on outside sources, lower costs, and a more resilient water supply in times of drought or scarcity.

Properly managed wastewater keeps rivers, lakes, and reservoirs free from excessive pollutants like heavy metals, oils, solvents, and nutrients that fuel harmful algal blooms. The western riverside county regional wastewater authority orchestrates these efforts, working with a network of treatment plants, sewer systems, and advanced filtration systems to catch and clean wastewater before it ever mixes with local waterways. These measures protect wildlife, support recreation, and ensure public health.

Overview of Riverside County Regional Wastewater Authority Systems

The Riverside County Regional Wastewater Authority (RCRWA) serves as the backbone of the region’s wastewater infrastructure. Overseeing several interconnected sewer systems, treatment plants, and discharge points, the authority ensures that every gallon of industrial wastewater is routed through a robust collection system before entering sensitive natural environments. With a mix of centralized and distributed facilities, they’re able to balance daily fluctuations in industrial output—even during peak seasons or emergencies.

RCRWA also plays a pivotal role in coordinating among government bodies, industries, and communities, leveraging the latest in water treatment technology. This regional approach reduces gaps in compliance and streamlines upgrades when new regulations or studies demand higher standards. By tracking metrics such as gallons per day, contaminant removal efficiency, and discharge compliance rates, the authority maintains transparency with the public and sets clear benchmarks for continuous improvement.

The Role of Treatment Plants and Water Authority in Industrial Waste Water Treatment Riverside

At the heart of Riverside’s water strategy are its well-designed treatment plants and the vigilant efforts of the water authority. These plants are not only responsible for processing millions of gallons of wastewater per day, but also for using complex biological, chemical, and mechanical systems to remove threats from industrial processes. Their operation protects downstream users, wildlife habitats, and even future generations from dangers that can persist in water for years.

The water authority works side by side with plant operators, regulatory agencies, and commercial facilities to ensure continuous compliance and to adopt the best available technologies. By investing in staff training, state-of-the-art monitoring, and community education, Riverside has risen as a model for safe, efficient, and forward-thinking water management. Their success is measured not just in gallons per day, but in healthier ecosystems and more satisfied residents.

Comparison of Water Quality Metrics Before and After Industrial Waste Water Treatment Riverside |

||

Metric |

Before Treatment |

After Treatment |

|---|---|---|

pH |

4.5 – 8.5 (variable) |

6.5 – 8.5 (stable) |

Contaminant Levels |

Elevated—heavy metals, oils, solvents |

Reduced—meets EPA & Water Act standards |

Biological Oxygen Demand (BOD) |

High—up to 300 mg/L |

Very low—below 20 mg/L |

How Western Riverside County Regional Wastewater Control Program Ensures Clean Water

Western Riverside County’s commitment to clean water is exemplified by its rigorous control program for industrial waste water. The entire sanitary sewer system relies on meticulously planned policies and technical solutions to intercept pollutants at their source, long before they can threaten rivers, groundwater, or the health of communities. Key to this effort is the wastewater source control program, which focuses on identifying, monitoring, and minimizing sources of industrial contamination.

The program’s scope covers everything from on-site inspections and monitoring at industrial facilities to enforcing strict discharge limits and providing education about pollution prevention. Close cooperation with significant contributors—such as manufacturing businesses and commercial facilities—ensures that everyone is working toward a shared mission: reducing the region’s overall pollution burden while making the most of the available water treatment capacity.

"Over 1 billion gallons of wastewater are processed each week in Riverside County—making advanced water treatment not just a necessity, but a community imperative."

Wastewater Source Control Program: Best Practices for Industrial Sites

Best practices are the foundation of an effective wastewater source control program. At the industrial level, this means continual assessment of chemical inventories, installing spill prevention systems, and properly training staff in response protocols. Facilities must also keep detailed records of their discharges and participate in regular audits by the wastewater authority. All these steps help to identify potential hazards well before they can enter the sewer system.

The control program also encourages industries to substitute hazardous materials with safer alternatives and to employ best-in-class recycling or recovery processes. Not only does this prevent costly regulatory actions—it strengthens a facility’s reputation, boosts efficiency, and aligns with community goals for sustainable development. By focusing on root-cause mitigation, Riverside’s approach ensures that long-term water quality goals are always within reach.

Sewer System Upgrades and Preventative Strategies for Water Quality Protection

Maintaining a robust and secure sewer system is an essential preventative strategy for water quality protection. The regional wastewater authority strategically invests in upgrades such as corrosion-resistant piping, smart sensors, and high-capacity pumping stations. These enhancements allow for early detection of leaks or blockages that could lead to environmental incidents or disrupt millions of gallons per day of orderly flow through the sanitary sewer system.

Preventative maintenance goes beyond new equipment. Scheduled inspections, infrastructure renewal projects, and real-time data collection all combine to anticipate challenges before they become crises. The result is a streamlined and resilient network that continually delivers on its promise—safeguarding Riverside’s water quality for all residents and businesses who depend on it.

Key Steps in Industrial Waste Water Treatment Riverside at Modern Treatment Plants

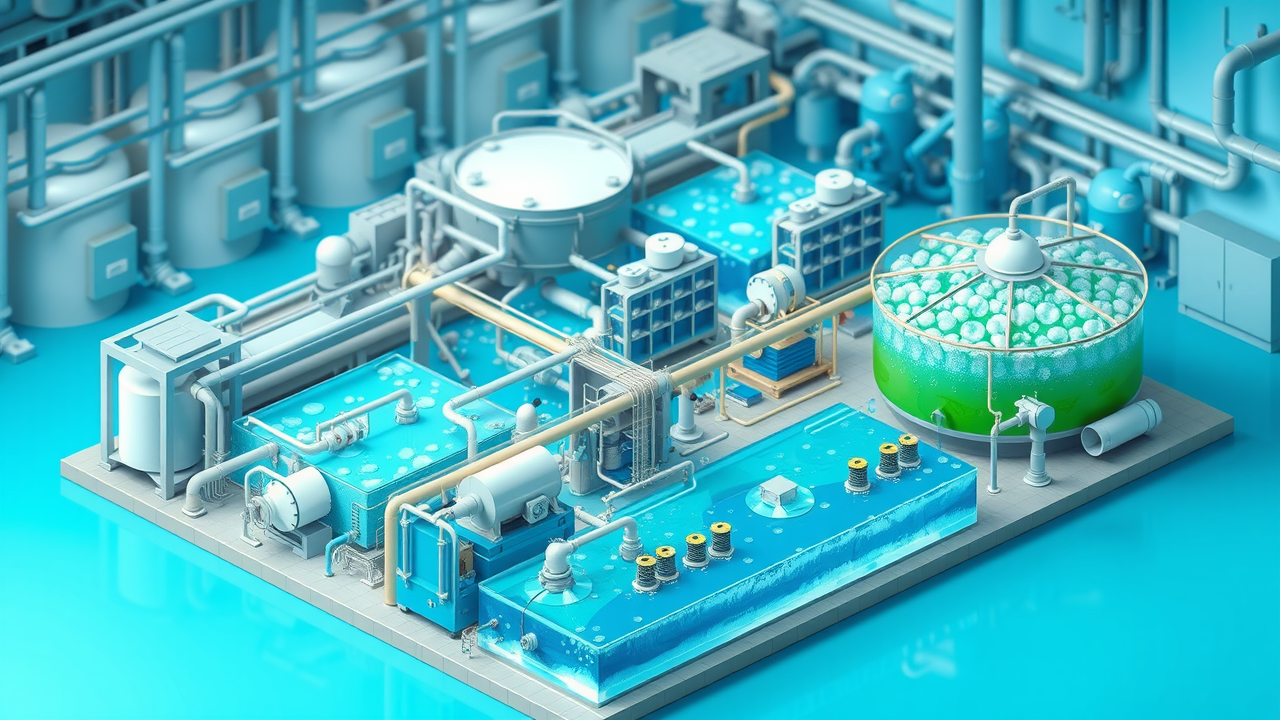

At the frontline of Riverside’s water quality defense are sophisticated treatment plants engineered to address the wide array of contaminants generated by industrial enterprises. Each day, these facilities manage millions of gallons per day, transforming potentially hazardous wastewater into water that’s safe for the environment. The journey of every drop is defined by a precise, highly regulated process—a process that begins the moment industrial effluent enters the collection system and continues through layers of mechanical and biological filtration.

Understanding these steps isn’t just important for industry professionals; it’s essential for local citizens and decision-makers as well. The more community members know about how water is protected, the better equipped everyone will be to advocate for upgrades, spot issues, and support water quality initiatives. From the very first pre-treatment screen to advanced polishing of treated water, these plants showcase Riverside’s commitment to sustainable resource management and public health.

Primary, Secondary, and Tertiary Treatment Explained

The treatment of industrial wastewater is typically divided into three main stages: primary, secondary, and tertiary treatment. Primary treatment removes large solids and grit through screening and sedimentation tanks. Here, heavy particles settle to the bottom while oils and grease are skimmed from the surface. This phase eliminates a significant portion of contaminants but cannot manage dissolved chemicals or biological hazards.

Secondary treatment uses living microorganisms to break down and consume organic pollutants. This biological process reduces Biological Oxygen Demand (BOD) and prepares the water for tertiary treatment, where advanced filtration—and sometimes chemical disinfection—removes any remaining nutrients, pathogens, and trace industrial compounds. This comprehensive stepwise approach ensures that every gallon leaving the treatment plant meets or exceeds state and federal water act standards, ready for safe discharge or occasional reuse.

Innovations in Water Treatment Technology for Riverside County

Rapid advances in water treatment technology are helping Riverside County stay ahead of new industrial challenges. Smart automation, remote monitoring systems, and real-time analytics have been integrated into plant operations, making it possible to instantly detect contaminants and optimize chemical usage. Membrane filtration and ultraviolet light disinfection are now commonplace, allowing for higher removal rates of emerging pollutants.

The embrace of innovative solutions—such as energy recovery from sludge and nutrient harvesting for agricultural reuse—transforms what was once waste into valuable resources. These upgrades enhance overall efficiency and reduce operational costs while reinforcing the county's reputation for environmental leadership. Collaboration with technology partners and academic institutions ensures that Riverside’s treatment plants continue to meet rising standards and complex industrial demands.

Pre-treatment and Screening

Primary Sedimentation

Biological Secondary Treatment

Advanced Filtration and Disinfection

Why Timely Industrial Waste Water Treatment Riverside Benefits Public Health and Business

Timely industrial waste water treatment Riverside provides a critical shield for public health by preventing hazardous chemicals and microbial contaminants from reaching drinking water and recreational areas. For businesses, effective wastewater management protects against legal risks and costly disruptions resulting from compliance violations. Quick intervention not only keeps the region's water quality high, but also preserves local economies from the crippling effects of pollution events or loss of public trust.

When industrial facilities partner with the regional wastewater authority to address waste concerns before problems escalate, the chances of fines and environmental liabilities diminish significantly. This forward-thinking approach creates a positive cycle where regulatory compliance goes hand-in-hand with reputation, attracting further investment and innovation to Riverside County.

Regulatory Compliance for Western Riverside Industrial Facilities

Preventing water pollution in Riverside relies on strict regulatory frameworks rooted in the water act , the pollution control program , and ongoing updates from federal and state agencies. All industrial facilities must adhere to discharge permits, reporting obligations, and routine inspections. Failure to follow these measures can result in substantial penalties, restricted operations, or even closure. The collaborative work of the regional wastewater authority, water authority, and local regulatory bodies is essential in enforcing these rules, thereby keeping the county's water safe.

By staying current with permit requirements and investing in state-of-the-art control program technologies, Riverside’s industries not only avoid disruptions but also signal their commitment to sustainable business practices. This foresight is recognized and rewarded by customers, regulatory bodies, and the wider community.

Avoiding Fines and Environmental Liabilities in Riverside

Riverside’s environmental regulations are rigorously enforced, and industrial polluters face steep fines or remediation costs if wastewater discharge exceeds set standards. Investing in proactive water treatment and partnering with the local county regional wastewater authority helps businesses not only comply with the law but also reduce their environmental liabilities. Regular plant upgrades, employee training, and adherence to sewer system best practices are key defenses against unforeseen incidents.

Beyond avoiding punitive action, proactive engagement builds community goodwill and futureproofs business operations. A clean environmental record paves the way for easier permitting, smoother expansion, and increased consumer trust—benefits that are invaluable in today’s highly regulated and eco-conscious marketplace.

Frequently Asked Questions About Industrial Waste Water Treatment Riverside

How does industrial waste water treatment Riverside help maintain water quality?

Industrial waste water treatment in Riverside intercepts contaminants from manufacturing and commercial processes before they can enter lakes, rivers, or groundwater. Treatment plants use advanced filtration, sedimentation, and biological processes to ensure that discharged water meets strict water quality standards. This protects wildlife, supports recreation, and ensures safe drinking water for the whole community.

What are the main steps involved in water treatment at Riverside plants?

Water treatment at Riverside plants involves several key stages: pre-treatment and screening, primary sedimentation to remove solids, biological secondary treatment for breaking down organic pollutants, and advanced tertiary filtration and disinfection. These steps collectively safeguard public health and the environment from industrial contaminants.

Who oversees industrial waste water treatment in Riverside County?

The Riverside County Regional Wastewater Authority plays a central role in managing industrial wastewater oversight. Alongside local water authorities and regulatory agencies, they set standards, conduct inspections, and ensure treatment plant compliance with all federal, state, and county regulations.

Top People Also Ask About Industrial Waste Water Treatment Riverside

What is the purpose of industrial waste water treatment in Riverside?

Industrial waste water treatment in Riverside is designed to remove contaminants from used water generated by local industries, ensuring discharged water meets environmental safety standards and protects community health.

What makes Riverside’s regional wastewater authority unique?

The regional wastewater authority in Riverside is a collaborative agency that coordinates county-wide efforts, investing in advanced treatment technologies and fostering partnerships to maintain high water quality standards.

How does Riverside enforce water quality standards for industrial wastewater?

Riverside enforces water quality standards through rigorous permits, inspections, and a comprehensive wastewater source control program ensuring industrial compliance at all levels.

Moving Forward with Industrial Waste Water Treatment Riverside: Support and Solutions

Don’t delay—proactive industrial waste water treatment in Riverside is crucial. Engage with your local water authority, support sustainable practices, and help safeguard the region’s future water quality today.

Sources

Riverside County Waste Resources – https://www.rivcowaste.org/

EPA: National Pollutant Discharge Elimination System – https://www.epa.gov/npdes

Riverside County Regional Conservation District – https://www.rcrcd.org/

Metropolitan Water District of Southern California – https://www.mwdh2o.com/

For a comprehensive understanding of industrial wastewater treatment in Riverside, consider exploring the following resources:

The City of Riverside’s Public Works Department provides detailed information on their Environmental Compliance program, which includes inspections, permitting, and monitoring to ensure that industrial wastewater discharges do not negatively impact the collection system or treatment plant. ( riversideca.gov )

The Western Riverside County Regional Wastewater Authority (WRCRWA) offers insights into their treatment plant operations, including capacity, treatment levels, and future plans for recycled water use. ( wrcrwa.org )

These resources offer valuable insights into the processes and regulations governing industrial wastewater treatment in Riverside, highlighting the collaborative efforts to maintain water quality and environmental health.

Add Row

Add Row  Add

Add

Write A Comment