Did you know that over 70% of industrial water treatment facilities cite dissolved air flotation wastewater complications as their top compliance barrier? Dissolved air flotation wastewater systems are considered game-changers in industrial water treatment—but when issues strike, inefficiency, compliance headaches, and even plant shutdowns aren’t far behind

A Startling Look at Dissolved Air Flotation Wastewater Challenges

When it comes to industrial dissolved air flotation wastewater treatment, it’s not just about keeping the machinery running—it’s about safeguarding operations, avoiding costly fines, and ensuring regulatory compliance. For many EHS and plant managers, DAF system complications can halt production or result in dire consequences, including environmental violations or mass equipment downtime. Problems such as inconsistent air bubble production, improper chemical dosing, and fluctuating flow rates can compromise the purity of effluent, risking everything from discharge permit breaches to community reputation.

Today’s strict local and federal wastewater treatment regulations leave little room for error with the operation of any flotation system. That’s why mastering the common pitfalls and maintenance requirements in dissolved air flotation systems is so vital: it’s the thin line between reliable operations and unexpected surprises. As this guide reveals, the most successful sites are those that quickly identify root causes and leverage systematic troubleshooting and modern monitoring to make rapid yet lasting improvements.

"Did you know that over 70% of industrial water treatment facilities cite dissolved air flotation wastewater complications as their top compliance barrier?" — Industry Analyst

What You'll Learn in Dissolved Air Flotation Wastewater Solutions

- The core principles of dissolved air flotation wastewater treatment

- Step-by-step troubleshooting for common dissolved air flotation issues

- How to maintain and optimize your flotation system for compliance

- Critical compliance concerns and how to overcome them

Understanding Dissolved Air Flotation Wastewater

What is Dissolved Air Flotation in Water and Wastewater Treatment?

Dissolved air flotation wastewater solutions rely on a fundamental process: introducing fine air bubbles into a wastewater stream so suspended solids, oils, or other contaminants bind to the rising bubbles and float to the surface for removal. This technique is especially valued in industrial wastewater and drinking water applications for its effectiveness at removing colloidal particles and suspended matter that might otherwise slip through conventional sedimentation methods. By saturating pressurized water with air, then releasing it into the flotation tank at atmospheric pressure, tiny bubbles form and adhere to contaminants, ushering them gently to the top—ready for skimming and disposal.

This process isn’t just about clean effluent; it’s prized for preparing water for final polishing stages and meeting the ever-tightening standards of industrial and municipal water treatment. In the words of an expert:

"Dissolved air flotation wastewater solutions remain one of the most effective technologies for removing suspended solids and oils from industrial effluent streams." — Water Treatment Engineer

Key Components of a Dissolved Air Flotation System

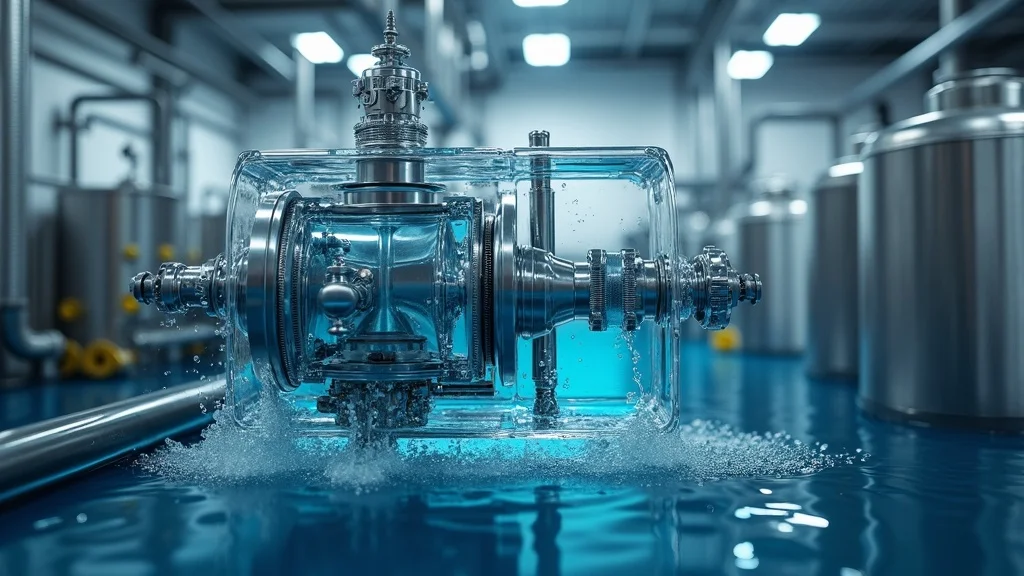

Dissolved Air Flotation System Overview

A typical DAF system blends mechanical ingenuity with chemical precision. The heart of every installation is the flotation tank, where pressurized, dissolved air-enriched water is introduced. The setup includes pumps, saturation vessels, air injection or dissolving mechanisms, sludge removal devices (often skimmers), and robust controls for adjusting flow rates and chemical dosing. Stainless-steel construction resists corrosive industrial environments, while sensors now play a pivotal role in monitoring pressures and flow. Whether treating industrial waste or municipal sewage, the well-choreographed dance of water, air, and chemistry ensures optimal suspended solids removal.

DAF systems efficiently handle wastewater streams with high oily content or difficult-to-settle colloidal particles. The precision balancing of air, chemicals, and flow ensures consistently high removal efficiency, supporting downstream processes and protecting critical infrastructure. As operational demands increase, technology upgrades allow sites to enhance real-time monitoring and automate routine tasks, reducing operator error and maximizing reliability.

Role of Air Flotation and Suspended Solids Removal

Air flotation in water treatment leverages the natural physics of buoyancy and adhesion. When air bubbles contact solid particles or oils in the wastewater, a surface attraction causes these tiny contaminants to latch on and rise together. These bubbles form a frothy layer on the surface of the flotation tank, making it easy to skim away suspended solids and return clarified water back to the process or environment.

This suspended solids removal mechanism is particularly vital in treating industrial wastewater, where variability in contaminant load demands a fast, flexible separation technology. Timely removal protects downstream processes, reduces chemical demand in later stages, and supports overall water treatment process efficiency. Consistent bubble size and even distribution are critical—if the balance is off, the DAF system can experience reduced performance and non-compliance events.

For those looking to further enhance their DAF system’s reliability, exploring advanced troubleshooting and maintenance strategies can make a significant difference. You can find practical guidance and proven solutions in the resources provided by CSI Environmental Inc, which specializes in optimizing industrial water treatment processes.

How DAF Systems Compare to Other Water Treatment Processes

Compared with other water treatment processes like sedimentation or filtration, dissolved air flotation provides distinct advantages in handling lighter, harder-to-settle contaminants. Sedimentation relies on gravity and is less effective at treating low-density particles. DAF, however, excels at separating suspended matter, making it a mainstay for heavy industrial waste streams, oily water, and high solids loads. DAF units can often operate at higher flow rates while still delivering exceptional effluent quality—an essential benefit for facilities dealing with fluctuating production schedules or diverse wastewater streams.

To choose the right treatment system, managers must weigh factors like removal efficiency, allowable footprint, energy use, and compliance requirements. The following table compares key aspects of DAF and alternative processes for industrial and drinking water treatment:

| Treatment Process | Removal Efficiency | Typical Flow Rate Capacity | Compliance Success Rate |

|---|---|---|---|

| Dissolved Air Flotation (DAF) | High (90-99%) for oils & suspended solids | High (varies by unit size; scalable) | Very High with proper maintenance |

| Sedimentation | Moderate (lower for light solids/oils) | Moderate to High | Moderate; issues with light particles |

| Membrane Filtration | Very High (removes most particles) | Lower (prone to fouling/clogging) | High if maintained; costly downtime |

How Dissolved Air Flotation Wastewater Processes Work

Fundamentals of the Dissolved Air Process

The core of the dissolved air flotation wastewater process is built on two principles: pressurizing water with air and then creating rapid decompression to form bubbles. First, a stream of water (often already partially treated) is saturated with air under pressure, causing dissolved gas to fully infuse into the liquid. This saturated water is then injected into the flotation tank where the pressure is released to atmospheric levels. As the pressure drops, tiny bubbles (20-80 microns in diameter) form almost instantly. These air bubbles are the workhorses of the DAF process: they attach to solid contaminants and float them to the surface.

This process works equally well for light suspended solids, fats, oils, and greases, thanks to the high surface area of the tiny bubble swarm. The result is a robust flotate that is easily skimmed, leaving behind clarified water ready for discharge or further treatment. The entire system, from air injection to skimmer operation, requires fine-tuned balance to ensure reliable wastewater treatment outcomes, underpinning compliance and plant sustainability.

Step-by-Step: The Flotation System in Action

- Pressurization and Saturation: Incoming wastewater stream is mixed with air and held in a pressure vessel until the air fully dissolves.

- Release and Bubble Formation: The mixture is released into the flotation tank at atmospheric pressure; this rapid decompression causes bubbles form instantly throughout the tank.

- Float Skimming and Solid Separation: Air bubbles bind to contaminants like oils or suspended solids, causing them to lift to the surface where they are mechanically skimmed off, leaving behind clarified water.

By maintaining consistent pressure, air saturation, and even chemical dosing, managers keep the DAF unit performing at its best. When variables like flow rates or chemical concentrations swing, so does the quality of separation, which highlights the need for vigilant monitoring and automated adjustment when possible.

Understanding Flow Rate and Its Impact on DAF System Efficiency

Flow rate is a critical factor in any dissolved air flotation wastewater operation. If the flow rates are too high, bubbles pass through too quickly and contaminants may not be fully lifted to the surface. Too slow, and the process is inefficient and costly. Optimal flow ensures that air bubbles and contaminants interact for maximum separation, while also enabling continuous operation without risk of DAF tank overflow or overload. Process data shows that fine-tuning the DAF unit’s flow rate can significantly increase removal percentages, translate to consistent compliance, and reduce chemical consumption.

Managers should always evaluate the manufacturer’s recommended specifications for their DAF system, and consider pressure, temperature, and contaminant load when adjusting flow. Routine flow rate assessments not only troubleshoot inefficiencies but help proactively prevent performance drops that could result in permit violations or unplanned shutdowns. The following table highlights the connection between flow rates and system removal efficiency:

| Flow Rate (gpm) | Removal Percentage (%) | Notes |

|---|---|---|

| 50 | 99 | Ideal for most industrial applications |

| 100 | 96 | Efficient; minor losses with certain contaminants |

| 150 | 92 | Some risk of breakthrough if solids load is high |

Common Dissolved Air Flotation Wastewater Challenges

Operational Issues in DAF Systems

Despite their robustness, DAF systems face a set of recurring issues that plant and maintenance managers must confront. Inconsistent bubble formation can dramatically reduce removal rates, while sludge buildup not only impairs system flow but can also cause equipment wear and costly downtime. Fluctuating flow rates—sometimes due to variations in production or influent water quality—can further destabilize separation performance.

Improper chemical dosing also makes the balance between effective contaminant removal and excessive sludge production a challenge. These operational headaches aren’t just a nuisance—they’re the direct cause of compliance issues, unplanned shutdowns, and rising operational costs. Recognizing the signs—foaming, excessive sludge, turbid effluent, or erratic system alarms—allows for swift action and heads off greater issues.

Troubleshooting Dissolved Air Flotation Performance Problems

Effective troubleshooting of dissolved air flotation wastewater systems begins with detailed observation. Operators should regularly check air injection system pressures, monitor for uneven bubbles form, and validate chemical dosing calibrations. If skimmers aren’t removing float consistently or sludge appears overly thick, the cause might be faulty DAF system mechanics or improper flotation tank cleaning routines.

Performance can also be affected by water temperature, influent load variability, and even changes in the dissolved air saturation process if upstream pumps begin to underperform. Logging operational data and observing trends—like gradual jumps in turbidity or dips in removal efficiency—can help pinpoint issues before they escalate. Cross-team communication, especially between maintenance and operations, is critical for thorough and timely troubleshooting.

Chemical Dosing and Suspended Solids Removal

The interplay between chemical treatment and suspended solids removal is one of the most pivotal in DAF system performance. Overdosing coagulants or flocculants can lead to poor separation, excess sludge, and increased costs. Conversely, underdosing risks failing to capture tiny oil droplets and fine industrial waste particles, eroding the performance of the entire flotation system.

By working closely with suppliers and leveraging process data, plant managers can optimize chemical usage while maintaining superb contaminant separation. Automated dosing pumps and responsive monitoring equipment help minimize operator guesswork, resulting in consistently high removal rates and strong regulatory compliance. The following list summarizes the most common DAF system problems encountered:

- Inconsistent bubble formation

- Sludge buildup

- Flow rates fluctuations

- Improper chemical treatment

Practical Solutions for Dissolved Air Flotation Wastewater Optimization

Best Practices in DAF System Maintenance

Routine maintenance is vital for ensuring dissolved air flotation wastewater systems operate at peak efficiency. The most effective plants prioritize regular cleaning of the flotation tank, thorough inspection and lubrication of moving parts (like skimmers and pumps), and verification that air injection and chemical dosing mechanisms are free from blockages. A proactive maintenance culture—backed by detailed schedules and performance logs—prevents the accumulation of industrial waste deposits and the build-up of problematic sludge.

Scheduling weekly or biweekly drainage and flushing of the system, especially after heavy contaminant loads, is highly recommended. Operators should also keep an eye on sensor calibrations and skimmer operation to preempt mechanical failures. Well-maintained DAF units not only run more efficiently but make troubleshooting future problems faster and less cumbersome—maximizing compliance and end-to-end water treatment process results.

Technology Upgrades for Air Flotation and Industrial Wastewater Treatment

Emerging technologies now offer game-changing capabilities for dissolved air flotation wastewater units. Upgrading to high-efficiency air dissolving mechanisms and installing advanced programming for dosing and flow management can boost system reliability and lower operational costs. Many leading sites are also adopting real-time sensors for tracking effluent quality, sludge thickness, and pressure changes—all of which feed valuable data back to operators and enable predictive maintenance.

Beyond mechanical enhancements, digitized controls and remote monitoring platforms empower maintenance managers to track key performance indicators from any location, enabling rapid response when parameters drift out of spec. Such investments not only ensure compliance but free up valuable human resources for continuous improvement initiatives rather than routine system firefighting.

Automation and Remote Monitoring in Flotation Systems

- Regular draining and cleaning schedules

- Automation integration recommendations

- Upgrading dissolved air injection mechanisms

Automated data logging, remote alarms, and even AI-driven fault detection are replacing the traditional “run-to-fail” maintenance model. This shift means fewer unexpected shutdowns, better resource allocation, and more consistent compliance for demanding industrial wastewater environments.

Compliance and Regulatory Considerations for Dissolved Air Flotation Wastewater

Meeting Local and Federal Wastewater Treatment Standards

Compliance remains at the forefront for any air flotation plant manager or EHS leader. Regulatory bodies enforce strict discharge limits for effluent quality, making it crucial to monitor dissolved air flotation wastewater performance metrics like suspended solids, oil content, chemical oxygen demand, and sludge volume. Meeting these local and federal standards isn’t just about passing audits—failure can result in steep fines, negative publicity, or even forced shutdowns.

By retaining and regularly reviewing effluent logs, conducting routine internal assessments, and utilizing online monitoring tools, managers can demonstrate proactive risk management. Staying ahead of evolving compliance requirements protects not only operations but also the company’s reputation with regulators and the surrounding community.

How a Compliance Assessment Can Prevent Fines and Shutdowns

Preemptive compliance assessments are more than just “box-ticking”—they are an essential line of defense against unforeseen disruptions. By enlisting environmental specialists to review system operations, maintenance documentation, chemical dosing, and effluent sampling, potential compliance gaps can be addressed before regulators arrive. These assessments also pave the way for targeted training, process improvements, and technology upgrades—making them a smart investment for any forward-thinking plant manager.

"Regulatory failures often cost plants far more than a preventative assessment ever would." — EHS Compliance Expert

Case Study: Success Stories in Dissolved Air Flotation Wastewater Management

How Industrial Waste Sites Overcame Flotation System Hurdles

One large industrial waste processing facility was facing consistent violations due to uneven suspended solids removal and excessive sludge accumulation. After a comprehensive compliance assessment, the site team implemented several key changes: automated flow monitoring, weekly system cleanings, and better chemical calibration. The turnaround was dramatic—not only did effluent quality improve overnight, but the number of compliance incidents dropped to zero in the following year. The team also reported a 20% reduction in energy costs thanks to more stable DAF unit operations.

This case underscores the broader industry lesson: when site and maintenance managers are empowered with the right diagnostics, timely maintenance, and a relentless focus on process optimization, compliance and cost savings naturally follow. Collaboration between plant teams and trusted water treatment partners proved invaluable during troubleshooting and upgrades, highlighting the power of a systems-based approach to dissolved air flotation wastewater management.

Lessons Learned from Water Treatment Process Optimization

Whether in food and beverage processing, petrochemical refining, or municipal services, high-performing sites share several traits: commitment to preventative maintenance, open communication between operators and compliance officers, and strategic adoption of automation. These lessons confirm that the most successful water treatment teams aren’t just reactive—they’re proactive, always seeking ways to reduce manual intervention and build greater process transparency. As dissolved air flotation wastewater technologies continue to evolve, this forward-thinking approach will remain a critical factor in both regulatory success and long-term plant efficiency.

People Also Ask About Dissolved Air Flotation Wastewater

What is dissolved air flotation in water and wastewater treatment?

Answer: Dissolved air flotation in water and wastewater treatment is a process that removes suspended solids, oils, and other contaminants by dissolving air into the water under pressure and releasing it at atmospheric pressure in a flotation tank. The released air forms tiny bubbles that adhere to the particles, causing them to float to the surface where they are removed.

What does DAF stand for in wastewater?

Answer: DAF stands for Dissolved Air Flotation, a key method in wastewater treatment used to separate suspended solids from liquids by introducing air bubbles to float the solids to the surface.

How often should a DAF be drained and cleaned?

Answer: A dissolved air flotation wastewater DAF unit should typically be drained and cleaned at regular intervals based on sludge load and process conditions, often weekly or as recommended by the system manufacturer to maintain efficiency and prevent buildup.

What are the disadvantages of dissolved air flotation?

Answer: Disadvantages of dissolved air flotation wastewater solutions include higher energy consumption compared to some methods, potential for chemical costs, and the need for regular maintenance and operator expertise to avoid operational issues.

FAQs About Dissolved Air Flotation Wastewater Systems

-

How does a flotation system fit into an overall treatment process?

A flotation system acts as a primary or secondary treatment step, removing suspended solids and oils before advanced filtration or biological processes. It is critical for protecting downstream treatment stages and supporting high effluent quality. -

What maintenance does a dissolved air flotation unit require?

DAF units require routine cleaning, regular inspection of pumps and injectors, calibration of chemical dosing, and periodic sensor verification to ensure consistent operation and compliance. -

Which industries benefit most from DAF systems?

Industries including food processing, oil and gas, chemical manufacturing, and municipal water treatment all benefit from DAF systems due to their ability to handle variable contaminant loads and achieve strict effluent standards. -

Are there innovations in dissolved air flotation system technology?

Yes, newer DAF systems offer advanced automation, real-time monitoring, remote alerts, and enhanced energy efficiency, driving better performance and lower operational costs in the water treatment sector.

Key Takeaways for Site and Maintenance Managers

- Dissolved air flotation wastewater treatment ensures compliance and operational efficiency.

- Regular maintenance and assessment of DAF systems avert costly downtime.

- Technology upgrades can significantly optimize air flotation performance.

Conclusion and Next Steps for Dissolved Air Flotation Wastewater Management

By prioritizing maintenance, regular assessments, and smart upgrades, site and plant managers can resolve DAF challenges swiftly—delivering cleaner water and confident compliance for years to come.

"An effective dissolved air flotation wastewater strategy means fewer compliance headaches and safer, cleaner plant operations for everyone involved." — Plant Manager

If you’re ready to take your water treatment strategy to the next level, consider exploring the broader environmental solutions and industry expertise available through CSI Environmental Inc. Their comprehensive approach goes beyond DAF systems, offering insights into integrated compliance, advanced technology adoption, and sustainable best practices for industrial facilities. By leveraging their knowledge, you can unlock new efficiencies and stay ahead of evolving regulatory demands. Dive deeper into their resources to discover how a holistic water management plan can transform your plant’s performance and resilience.

Get Your Water Disinfection Systems

Ready for fast solutions and reliable compliance? Get Your Complete Waste Water Assessment now

Sources

- EPA - Wastewater Treatment Research – https://www.epa.gov/water-research/wastewater-treatment-water-research

- WaterWorld – Choosing the Best DAF System for Your Application – https://www.waterworld.com/home/article/14304597/choosing-the-best-daf-system-for-your-application

- Lenntech - Dissolved Air Flotation – https://www.lenntech.com/dissolved-air-flotation.htm

- Water Tech Online – Understanding DAF Systems – https://www.watertechonline.com/industrial/article/15542322/understanding-dissolved-air-flotation-daf-systems

- SUEZ Water Technologies – Dissolved Air Flotation – https://www.suezwatertechnologies.com/solutions/equipment-products/dissolved-air-flotation

Dissolved Air Flotation (DAF) is a water treatment process that clarifies wastewater by removing suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which adhere to the suspended matter, causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device. (en.wikipedia.org)

DAF systems are widely used in treating industrial wastewater effluents from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills, and similar industrial facilities. They are particularly effective in removing suspended solids, oils, and greases, achieving removal efficiencies of up to 95%. (westlakeenv.com)

The process involves saturating a portion of the clarified effluent water leaving the DAF tank with air under pressure. This air-saturated water is then recycled to the front of the float tank and released at atmospheric pressure, resulting in the formation of tiny bubbles that attach to suspended particles, causing them to float to the surface for removal. (en.wikipedia.org)

DAF systems can be categorized as circular or rectangular. Circular DAF units are more efficient, requiring just 3 minutes of retention time, while rectangular units require 20 to 30 minutes. The circular type often features a spiral scoop for sludge removal. (en.wikipedia.org)

In the oil industry, dissolved gas flotation (DGF) units use gases other than air, such as nitrogen, to reduce the risk of explosion. (en.wikipedia.org)

Overall, DAF systems are a versatile and effective solution for clarifying wastewater by removing suspended solids, oils, and greases, thereby improving water quality and ensuring compliance with environmental regulations.

Add Row

Add Row  Add

Add

Write A Comment