Did you know that modern commerce DAF systems can remove up to 90% of industrial wastewater pollutants? This level of efficiency not only shrinks compliance risks but can also slash operational costs—making these systems a game-changer for today’s water and wastewater treatment operations

Startling Statistics: Why Commerce DAF Systems are Transforming Water Treatment Today

"Up to 90% of industrial wastewater pollutants can be removed using modern commerce DAF systems, dramatically reducing compliance risks and operational costs." — Steve Manii, CSI Environmental

New data shows that facilities using commerce DAF systems consistently outperform conventional treatment solutions across multiple key metrics. With growing regulatory pressure, the ability to cut suspended solids, oils and grease, and hazardous substances by up to 90% is more than just an advantage—it's a necessity. Commerce DAF systems offer reliable, scalable performance, leading to fewer compliance violations and significant OPEX savings. This is why more EHS, operations, and plant managers are switching to dissolved air flotation (DAF) technology.

Recent studies highlight that not only are commerce DAF systems more compact than older wastewater treatment systems, but they can also handle fluctuating flow rates and varying levels of contaminants with ease. This adaptability, combined with streamlined operator involvement and automated monitoring, means greater control, fewer shutdowns, and improved long-term sustainability for industrial and municipal plants.

What You'll Learn About Commerce DAF Systems and Water Treatment

- The core technology and design behind commerce DAF systems

- Key benefits for both water treatment and wastewater treatment applications

- How commerce DAF systems ensure industrial wastewater compliance and operational efficiency

- Real-world performance data, maintenance tips, and ROI details

Commerce DAF Systems Explained: Technology Designed for Water and Wastewater Treatment

What is a DAF System?

- Definition of commerce DAF systems and their function in dissolved air flotation

- Role in water and wastewater treatment processes

- Connection with dissolved air flotation systems and air flotation system efficiencies

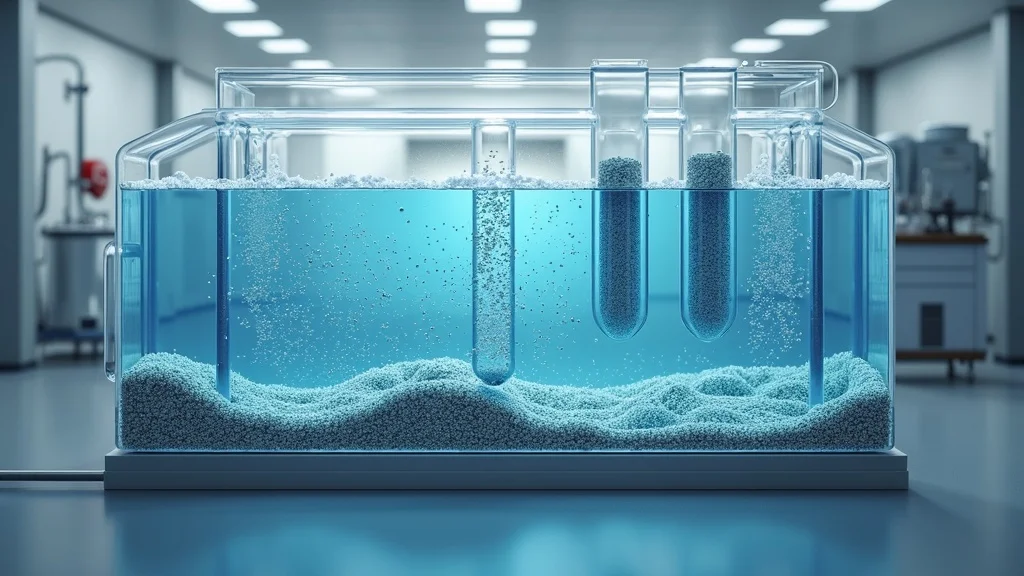

A DAF system, or Dissolved Air Flotation system, is an advanced treatment solution designed to remove suspended solids, oils, and grease from water and wastewater using the principle of dissolved air flotation. In a commerce DAF system, microbubbles are generated by dissolving air under pressure and then releasing it at atmospheric pressure in a flotation tank or basin.

When contaminants come in contact with these microbubbles, they adhere to the bubbles and float to the surface, where they are easily skimmed off. This technology stands out from other flotation systems due to its high efficiency, especially in industrial wastewater and municipal water treatment applications. The effectiveness of commerce DAF systems makes them a preferred solution in the paper mill industry and other sectors where compliance and reliability are essential. Their role has become increasingly vital as regulations on effluent quality tighten and as businesses seek to enhance both their operational efficiency and environmental stewardship.

For a deeper dive into the specific engineering and operational features that set DAF systems apart, you can explore the comprehensive overview provided by CSI Environmental Inc, which details system configurations, automation options, and real-world performance benchmarks.

What Does DAF Stand For?

- Breakdown of the term: Dissolved Air Flotation (DAF)

- Why air flotation and dissolved air techniques matter for treatment solutions

DAF stands for "Dissolved Air Flotation." This method utilizes the solubility of air in water under pressure—often called "dissolving air"—and then releases it so microbubbles form. These air bubbles attach themselves to suspended solids, causing them to rise. Air flotation systems play a fundamental role in the removal of difficult-to-treat contaminants that would otherwise slip through standard mechanical or biological treatment processes.

Dissolved air techniques are crucial because they provide a highly effective, chemical-lean method to achieve regulatory limits for total suspended solids (TSS), biochemical oxygen demand (BOD), and chemical oxygen demand (COD). In essence, commerce DAF systems deliver powerful, flexible water and wastewater treatment that adapts to variable influent characteristics—solving challenges in both compliance and operational efficiency.

Key Components and Operating Principles of Commerce DAF Systems

The Science of Dissolved Air and Effective Pollutant Removal

- How dissolved air introduces microbubbles to separate suspended solids

- Differentiation from other flotation systems and DAF system variants

- Features tailored for paper mill and industrial wastewater applications

At the heart of a commerce DAF system lies its ability to saturate water with dissolved air. When this pressurized water is released into the flotation tank, microbubbles quickly form. These air bubbles are the secret to DAF's effectiveness—they attach to suspended solids, reducing their density and making them rise efficiently to the water’s surface for removal.

Unlike traditional sedimentation or mechanical filtration, the dissolved air flotation system excels with a broad spectrum of wastewater including heavy influent streams, oils and grease, or highly variable loads, commonly found in paper mill or food processing wastewater. Key features, such as energy-efficient air dissolution units, automatic skimmers, and robust tank design, set commerce DAF systems apart from older methods or basic flotation systems. These features not only optimize performance but also dramatically reduce downtime and maintenance, making them ideal for demanding industries that rely on consistent, trouble-free operation.

Table: Comparing Commerce DAF Systems to Conventional Water Treatment Solutions

| Features | Commerce DAF Systems | Conventional Treatment System |

|---|---|---|

| Suspended Solids Removal | Up to 99% | Varies (70%-85%) |

| Footprint | Compact | Larger |

| OPEX | Lower | Higher |

| Compliance Risk | Minimal | Moderate/High |

| Operator Involvement | Low | High |

Commerce DAF Systems vs. Alternative Flotation Systems: What Sets Them Apart?

Efficiency in Wastewater Treatment

- Advantages in TSS, COD, and BOD reduction (using data-driven examples)

- Role in enabling industrial wastewater compliance

Commerce DAF systems deliver unmatched performance in wastewater treatment, particularly for challenging industrial wastewater. Data from installations in food processing and paper mill operations indicate up to 99% suspended solids removal and reductions of over 80% in BOD and COD values. This level of efficiency is crucial for meeting strict discharge permits and minimizing compliance risks.

Unlike standard air flotation systems, commerce DAF systems integrate fine-tuned air dissolution, automated controls, and smart skimming technology. This allows operators to adapt to rapid changes in influent quality or flow rate, ensuring effluent limits for TSS, BOD, and COD are consistently met even during peak production cycles. For plant managers seeking a solution that both achieves and sustains industrial wastewater compliance, commerce DAF systems are a proven and future-ready choice.

System Longevity and Maintenance

- How often should a DAF be drained and cleaned?

- Commerce DAF systems vs. dissolved air flotation systems in maintenance downtime

Maintenance is a critical factor in the long-term viability of any water treatment solution. Most commerce DAF systems are designed for ease of service, with automated cleaning mechanisms and intuitive interfaces. Typically, a DAF system should be inspected daily and drained and cleaned every 2 to 4 weeks, depending on load and influent characteristics. Compared to older dissolved air flotation systems, modern DAF units from suppliers like CSI Environmental require less downtime for routine maintenance, thanks to corrosion-resistant materials, modular skimming arms, and self-diagnostics.

Efficient maintenance protocols are key not only for reliability but also for extending equipment lifespan and minimizing unplanned interruptions. Scheduling regular inspection and proactive cleaning protocols—as recommended by manufacturers—can add several years to a system’s operational life.

"Regular inspection and proactive cleaning can extend a commerce DAF system's operational life by several years." — Steve Manii

Commerce DAF Systems Applications Across Industry Sectors

- Industrial wastewater and paper mill treatment

- Food and beverage processing

- Pulp and paper industries

- General municipal water and wastewater treatment solutions

Commerce DAF systems are the backbone of efficient wastewater treatment and water treatment solutions across many sectors. Leading paper mills have reduced their effluent violations and sludge disposal costs by installing high-capacity DAF systems. In food and beverage processing, where oils and grease can hamper traditional treatment, DAF technology provides an effective solution to ensure compliant, odor-free effluent.

Other sectors—such as pulp and paper and municipal water treatment—also leverage commerce DAF for treating large volumes and fluctuating contaminant levels. Because these systems are scalable and modular, upgrading to a modern dissolved air flotation system can be as simple as retrofitting an existing wastewater treatment plant with new DAF modules. This versatility has made commerce DAF systems the preferred approach for both greenfield facilities and plant upgrades where space, efficiency, and compliance are top priorities.

Understanding Commerce DAF System Pricing and ROI

Key Factors Affecting Pricing

- System design, capacity, and automation

- Installation requirements and maintenance contracts

- Comparison with traditional water treatment solutions

The cost of a commerce DAF system depends on multiple variables. Core factors include the desired treatment capacity (flow rate), level of automation, and the complexity of the plant layout. Advanced DAF systems with remote monitoring, automatic sludge removal, and integrated pH control command higher upfront costs, but these features dramatically improve reliability and lower long-term operating expenses.

Installation requirements—such as available space, utility access, and need for pretreatment—impact setup costs. Opting for full-service maintenance contracts can help reduce downtime and enhance lifespan, further boosting your ROI compared to basic treatment systems. Compared to traditional clarifiers or sedimentation tanks, commerce DAF systems offer a compelling package of superior contaminant removal, a smaller physical footprint, and lower OPEX month-over-month.

Table: Real-World ROI Outcomes From Commerce DAF System Installations

| Metric | Before DAF Install | After DAF Install |

|---|---|---|

| Compliance Violations/Year | 7 | 0 |

| OPEX/Month | $10,000 | $4,500 |

| Operator Hours/Week | 20 | 6 |

How to Select the Right Commerce DAF System for Water and Wastewater Treatment Needs

- Analyze influent characteristics (TSS, BOD, COD, pH)

- Assess available infrastructure and space

- Define compliance and operational targets

- Consult with specialists like CSI Environmental

Consider your facility's infrastructure: Is there enough space for DAF installation? Can the existing utilities support the upgraded system?

Is reducing operator hours or minimizing maintenance downtime more critical to your plant? Or is it imperative to achieve stringent zero-discharge or ultra-low effluent limits? Finally, collaborate with experienced vendors such as CSI Environmental to get a custom, data-driven recommendation for your exact application

Commerce DAF Systems in Action: Customer Stories and Reviews

- Case study: Industrial wastewater treatment success in paper mill

- Plant manager testimonials on system performance

- Summary of compliance and cost-saving achievements

A major paper mill in the Pacific Northwest faced recurring compliance violations and excessive sludge hauling costs with its legacy wastewater treatment system. After consulting with CSI Environmental, the team installed a modern commerce DAF system, fully automated with remote monitoring. Within six months, compliance violations dropped to zero and OPEX was cut by more than 55%.

Plant managers rave about the increased reliability and ease of operation. “We went from daily troubleshooting and frequent shutdowns to largely hands-off monitoring. The air flotation technology with advanced microbubble generators delivered cleaner effluent and less operator strain,” reported the facility’s EHS manager. These outcomes are echoed across food processing, municipal, and pulp and paper sectors, where commerce DAFs ensure compliance—and peace of mind—for plant operators.

Expert Insights: Steve Manii on Commerce DAF Systems, Operation, and Optimization

"Plant managers consistently report transformative results after adopting CSI Environmental’s commerce DAF systems — both in environmental compliance and reduced total cost of ownership." — Steve Manii

Steve Manii, lead systems engineer at CSI Environmental, emphasizes that DAF technology is not a one-size-fits-all proposition. “Customization and proactive maintenance are key to extracting the full value of commerce DAF systems. With the right design and operational support, DAF systems unlock ROI far beyond initial expectations.”

The combination of data-driven customization and strong after-sales engineering support sets CSI Environmental apart, making commerce DAF systems the preferred choice for plants where compliance isn’t optional.

All About DAF Operators: Roles, Certifications, and System Management

What is a DAF Operator?

- Core responsibilities managing dissolved air flotation systems

- Certification and skills required

- How technology is making the DAF operator’s role more strategic

A DAF operator oversees the day-to-day functioning of dissolved air flotation systems—ensuring all components are running at optimal pressure, dissolved air levels are maintained, and that solid waste is removed efficiently. Certification typically involves completion of standardized safety and operations training, sometimes supplemented with coursework on best practices for water and wastewater treatment systems.

Today’s commerce DAF systems are highly automated, allowing operators to focus less on manual intervention and more on overall system optimization, regulatory reporting, and process improvement. As plants move toward digitalization, the DAF operator’s role expands into a strategic operational partner—using system data to guide troubleshooting and maximize performance.

Top Maintenance and Troubleshooting Tips for Commerce DAF Systems

- Routine inspection protocol (daily/weekly/monthly)

- Checklist: Cleaning, draining, and dissolved air system calibration

- Common issues and expert troubleshooting guidance

To keep your commerce DAF system running smoothly, follow a structured maintenance schedule. Perform daily visual inspections for leaks, excessive bubbles in the flotation tank, or abnormal sounds. Weekly, drain the primary sludge compartment and check for any blockages in the skimming system. Monthly, calibrate dissolved air injectors, inspect the integrity of the pressure vessel, and verify pH control circuits.

A typical troubleshooting list includes checking for loss of flotation efficiency (caused by undersized or fouled diffusers), correcting air-to-solids ratios, and keeping all automatic valves and sensors free from accumulation. Partner with your supplier for remote diagnostics and annual upgrades—CSI Environmental provides tailored support packages to ensure peak performance for every installation.

Frequently Asked Questions: Commerce DAF Systems and Wastewater Treatment

-

How does dissolved air flotation compare to other water treatment solutions?

The DAF system excels where traditional clarifiers fall short, removing even fine and greasy particles with up to 99% efficiency. DAF is especially effective for industrial wastewater streams, oils and grease, and when space is at a premium. -

What regulations do commerce DAF systems help meet?

Commerce DAF systems help plants achieve regulatory standards for TSS, BOD, COD, pH, and are widely used to ensure NPDES, EPA, and state-level discharge compliance in the U.S. -

Can commerce DAF systems be retrofitted to existing wastewater treatment plants?

Yes. DAF modules are highly adaptable and can be retrofitted to supplement or replace failing clarifiers and air flotation systems in both industrial and municipal facilities. -

What support does CSI Environmental offer after installation?

CSI Environmental provides full training for operators, ongoing technical support, scheduled maintenance plans, remote system monitoring, and annual site audits to ensure lasting ROI and compliance.

Key Takeaways: Unlocking Compliance and Value with Commerce DAF Systems

- Commerce DAF systems provide superior removal of suspended solids for both water and wastewater treatment

- Industry-leading compliance, efficiency, and ROI features

- Supported by CSI Environmental expertise and real-world results

Get a Complimentary Compliance and Wastewater System Assessment Now

- Analysis of current TSS, COD, BOD, and pH levels

- Identification of compliance risks before they become violations

- Cost-saving opportunities based on proven results

- Clear ROI projections for any recommendation

- Contact: (626) 608-7603

Get a complimentary wastewater system assessment that includes: ✅ Analysis of current TSS, COD, BOD, and pH levels ✅ Identification of compliance risks before they become violations ✅ Cost-saving opportunities based on proven results ✅ Clear ROI projections for any recommendation | (626) 608-7603

Conclusion

Adopting commerce DAF systems ensures regulatory compliance, operational savings, and a sustainable future for water and wastewater treatment—take the next step with CSI Environmental today.

If you’re ready to elevate your facility’s water or wastewater treatment strategy, consider exploring the broader solutions and industry expertise available through CSI Environmental Inc. Their extensive experience in environmental engineering and system integration can help you navigate complex compliance requirements and future-proof your operations. Whether you’re seeking advanced automation, tailored maintenance programs, or holistic plant upgrades, their team offers the insight and support to maximize your investment. Take the opportunity to discover how a partnership with a trusted environmental solutions provider can unlock new levels of efficiency and sustainability for your organization.

Sources

- EPA - NPDES Permits

- CSI Environmental – DAF Systems Overview

- Water Online – How to Improve Industrial Wastewater Treatment with DAF

- Treatment Plant Operator – Deciding if a DAF System is Right for Your Facility

Incorporating advanced dissolved air flotation (DAF) systems into your water and wastewater treatment processes can significantly enhance efficiency and compliance. For instance, the Ecologix E-DAF System utilizes pressurized, air-saturated water to generate microscopic air bubbles that attach to suspended solids, fats, oils, and greases, causing them to float to the surface for easy removal. This method effectively reduces contaminants and improves water clarity. (ecologixsystems.com)

Additionally, Ecologix Environmental Systems offers a range of DAF systems tailored to various industrial applications, including food and beverage processing, oil and gas, and pulp and paper industries. Their E-Series DAF models are designed to handle flow rates from 130 to 3,700 gallons per minute, providing scalable solutions for diverse operational needs. (ecologixsystems.com)

If you’re serious about optimizing your water treatment operations, these resources will provide valuable insights into the benefits and applications of modern DAF systems.

Add Row

Add Row  Add

Add

Write A Comment