Did you know over 50% of industrial facilities face wastewater compliance issues every year?For plant managers and Environmental Health & Safety (EHS) professionals, understanding the wastewater compliance notification process is critical to preventing costly penalties and operational shutdowns. Wastewater compliance notification acts as an early warning system that helps facilities identify violations related to standards mandated by federal and local environmental laws. This article breaks down what to expect from receiving a government compliance notice, the regulatory frameworks involved, common compliance challenges, and expert strategies to ensure your facility stays operational and compliant.

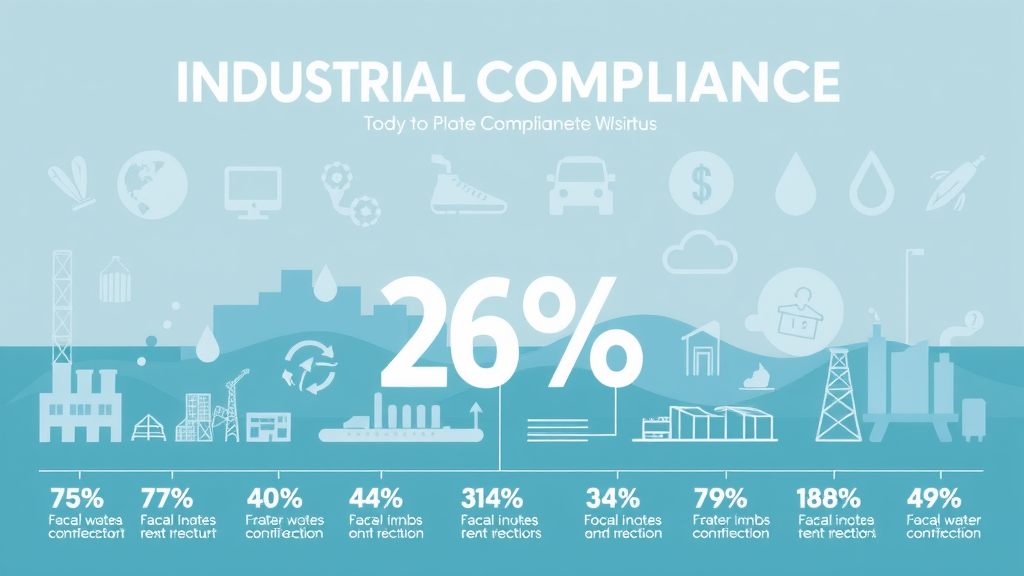

Startling Facts About Wastewater Compliance Notification

Over 50% of industrial facilities face wastewater compliance issues annually.

Non-compliance can lead to hefty fines, operational shutdowns, and public disclosure.

Wastewater compliance notification is governed by federal and local regulations, including the Clean Water Act.

Overview of Wastewater Compliance Notification and Federal Regulations

Wastewater compliance notification refers to the formal communication sent by regulatory agencies when a facility’s wastewater discharge fails to meet mandated environmental standards. This process is essential to ensure that industrial wastewater treatment meets the thresholds designed to protect water quality and public health. At the heart of these regulations is the Clean Water Act, a federal law that sets the baseline wastewater treatment standards across the United States.

While the Clean Water Act establishes national standards, states and counties have the authority to impose stricter limits. For example, counties like Los Angeles and Riverside in California enforce more stringent wastewater treatment requirements than the federal baseline. These local regulations respond to specific environmental needs and pollution targets unique to their regions.

Steve Manii of CSI Environmental explains, "The federal mandate is the baseline, but counties like Los Angeles and County can set more stringent wastewater treatment standards."

Key Parameters Monitored in Wastewater Treatment Compliance

Fats, Oils, and Grease (FOG)

Chemical Oxygen Demand (COD)

Biochemical Oxygen Demand (BOD)

Total Suspended Solids (TSS)

pH levels

Sulfide

Step-by-Step Breakdown of the Wastewater Compliance Notification Process

The wastewater compliance notification process begins with sampling and can escalate if violations remain unaddressed. Understanding each step helps plant managers and EHS professionals prepare timely responses and corrective actions:

Initial 24-hour composite sampling by local water district. Regulatory bodies collect samples over 24 hours to evaluate wastewater quality accurately.

Detection of out-of-compliance parameters. Samples revealing excessive levels of FOG, COD, BOD, TSS, or abnormal pH values trigger a compliance alert.

Issuance of a written warning detailing violations and required action plans. The facility receives a notice specifying the nature of the violation and instructions to resolve the issue.

Retesting to confirm resolution of issues. After corrective measures, follow-up sampling ensures compliance has been restored.

Escalation procedures if non-compliance persists. Repeated violations lead to stricter enforcement actions, including fines or shutdowns.

According to Steve Manii, "If you're out of compliance, the regulatory agency sends a written warning with an action plan and requires a retest to ensure the issue is resolved."

Common Causes of Wastewater Compliance Violations

Higher than permissible amount of sulfide. Without chemical treatment with agents like chlorine, sulfide cannot be safely neutralized or removes.

Exceeding permitted levels of COD, BOD, or TSS. Ongoing process issues or inadequate treatment can cause these critical parameters to surpass acceptable limits.

pH levels outside the acceptable range. Discharges typically must maintain a pH between 6 and 9–10; excursions can damage local ecosystems and violate permits.

Consequences of Non-Compliance with Wastewater Treatment Regulations

Failing to respond to wastewater compliance notifications carries significant operational, financial, and reputational risks. Regulatory agencies follow a progressive enforcement approach:

Follow-up warnings and increasingly stringent notices. Continued non-compliance results in escalated communications and deadlines.

Fines and fees imposed by regulatory agencies. Monetary penalties can accumulate rapidly depending on severity and duration.

Potential operational shutdowns until compliance is achieved. Facilities risk forced closure affecting business continuity.

Public disclosure of non-compliant companies. In regions like LA County, lists of violators are published in LA Times, harming corporate reputation.

Expert Insights: How CSI Environmental Supports Wastewater Compliance

CSI Environmental, Inc. provides critical expertise to help facilities navigate compliance challenges with effective treatment solutions. Their approach includes extensive consultation and tailored recommendations based on each facility's unique discharge profile.

For instance, to address sulfide violations, CSI Environmental often suggests chemical neutralization techniques such as injecting chlorine or hydrogen peroxide upstream of discharge points. Additionally, they recommend implementing equipment that reduces Total Suspended Solids (TSS), Chemical Oxygen Demand (COD), and Biochemical Oxygen Demand (BOD), improving overall treatment efficiency and compliance.

Aside from technical solutions, CSI Environmental acts as a trusted third-party liaison with regulatory agencies. This service eases communication burdens on plant managers and EHS staff, ensuring clarity and cooperation throughout the compliance process.

Steve Mani of CSI Environmental states, "We consult with businesses to offer cost-effective ways to neutralize sulfides and reduce TSS, COD, and BOD to achieve compliance."

Who Typically Receives Wastewater Compliance Notifications Within a Company?

Environmental Health and Safety (EHS) Managers or Supervisors

Maintenance Department responsible for wastewater treatment

Plant Managers or Site Directors

Preparing for a Compliance Consultation: Essential Documentation and Information

Proper preparation is key when seeking expert assistance for wastewater compliance issues. Facilities should gather relevant documents to facilitate a thorough evaluation:

Recent third-party lab reports, ideally covering the last 3 to 6 months, to analyze trends and pinpoint violations.

Written compliance notices received from regulatory agencies to understand specific violations and required actions.

Surcharge statements detailing charges related to TSS, COD, and BOD, which help identify opportunities for cost savings.

Facility’s permitted discharge levels for comparison with actual lab results and compliance status.

Cost Savings and Benefits of Achieving Wastewater Compliance

Beyond avoiding penalties, wastewater compliance offers significant financial and operational benefits. Proper treatment can dramatically reduce surcharge fees and improve plant efficiency.

Parameter |

Typical Reduction Range |

Impact on Costs |

|---|---|---|

Total Suspended Solids (TSS) |

90-95% |

Significant surcharge fee reduction |

Chemical Oxygen Demand (COD) |

50-85% |

Moderate cost savings, dependent on soluble content |

Biochemical Oxygen Demand (BOD) |

50-85% |

Moderate cost savings, dependent on wastewater characteristics |

Facilities regularly achieving these reductions commonly see a positive impact on the bottom line and enhanced environmental stewardship.

People Also Ask (FAQs) About Wastewater Compliance Notification

What is wastewater compliance? Wastewater compliance refers to adhering to regulatory standards for the treatment and discharge of wastewater to protect water quality and public health.

Are EPA violations public record? Yes, EPA violations are often public record and can be published by regulatory agencies, impacting a company's reputation.

What is the name of the US law that requires regular monitoring of treated wastewater that is discharged into a US river? The Clean Water Act mandates regular monitoring and compliance for treated wastewater discharged into US waters.

When assessing projects which may be covered by the Clean Water Act, compliance may require permits from which of the following agencies? Permits may be required from federal, state, and local agencies including the EPA, state environmental agencies, and local water districts.

Common Mistakes and Misconceptions in Wastewater Compliance

Assuming federal standards are the only requirements without considering stricter local regulations.

Ignoring early warning notices leading to escalated penalties.

Underestimating the complexity of wastewater treatment and the need for expert consultation.

Actionable Tips for Managing Wastewater Compliance Notifications

Respond promptly to compliance notifications with a detailed action plan.

Maintain regular monitoring and documentation of wastewater parameters.

Engage with environmental consultants like CSI Environmental early to develop effective treatment solutions.

Keep open communication with regulatory agencies to avoid surprises.

Key Takeaways

Wastewater compliance notification is a critical process governed by federal and local regulations.

Early detection and response to violations can prevent costly fines and operational disruptions.

Expert consultation and proper treatment systems are essential for sustained compliance.

Maintaining thorough documentation and communication with regulators supports successful compliance management.

Conclusion: Ensuring Compliance to Protect Your Business and the Environment

Understanding the wastewater compliance notification process empowers businesses to act decisively.

Proactive management and expert support reduce risks and enhance operational efficiency.

Compliance not only meets legal obligations but also demonstrates environmental responsibility.

Get Your FREE Compliance Assessment Today

Contact CSI Environmental for a personalized consultation.

Visit https://csienvironmentalinc.com/California-Wastewater-Compliance or call (800) 690-2436.

Take the first step towards achieving and maintaining wastewater compliance.

Understanding the wastewater compliance notification process is crucial for facilities to maintain regulatory adherence and avoid penalties. The U.S. Environmental Protection Agency (EPA) provides comprehensive guidelines on compliance monitoring under the Clean Water Act, detailing the responsibilities of facilities in managing wastewater discharges. (epa.gov)

Additionally, the Connecticut Department of Energy & Environmental Protection offers specific notification requirements for industrial wastewater compliance, including procedures for reporting noncompliance and equipment malfunctions. (portal.ct.gov)

By consulting these resources, facilities can gain a clearer understanding of their obligations and the steps necessary to address compliance notifications effectively.

Add Row

Add Row  Add

Add

Write A Comment