Get Our Industry Assessment

The Problem...

Wastewater is one of the most overlooked risks in plant operations. When it goes wrong, the consequences are immediate:

- Costly surcharge fees and hauling costs

- Surprise compliance violations and audits

- Odor complaints from employees or neighbors

- Downtime that halts production

- You weren’t hired to be a wastewater expert—yet you're expected to keep everything running. That’s where we come in.

The Solution

- Costly surcharge fees and hauling costs

- Surprise compliance violations and audits

- Odor complaints from employees or neighbors

- Downtime that halts production

- You weren’t hired to be a wastewater expert

How It Works...

We start with a free on-site evaluation to uncover inefficiencies in your wastewater system. Then, we build a custom plan to optimize performance, reduce costs, and ensure compliance—so your team can focus on running the plant, not reacting to problems.

- Schedule a Site Evaluation – We identify system weak points and cost drains

- Get a Custom Wastewater Plan – We design a tailored treatment and support strategy

- Start Seeing Results – Improved performance, reduced costs, and full compliance

What Success Looks Like:

Your plant stays compliant, surcharges drop, and your system runs efficiently—without the constant stress of surprise breakdowns or violations. Your team has the confidence and support they need to stay ahead of problems instead of chasing them.

- You stay ahead of compliance deadlines

- Your team stops reacting to emergencies

- Your hauling, chemical, and surcharge costs drop

- You gain control of an area that used to feel out of control

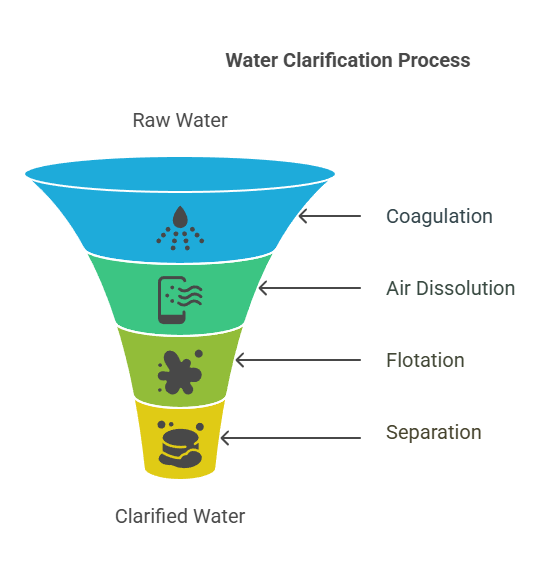

The Dissolved Air Flotation (DAF) Process

DAF is a water treatment method that removes suspended solids, oils, and other impurities by introducing microbubbles that attach to the particles and float them to the surface for easier removal. This technology is effective in various applications, including wastewater treatment and desalination.

Learn More About The DAF Process...

COAGULATION & FLOCCULATION

Chemicals are added to the water to cause small particles to clump together into larger, more easily removable flocs.

AIR DISSOLUTION

Air is dissolved into the water under pressure.

FLOTATION

When the pressure is released, the dissolved air forms microbubbles that attach to the flocs and other suspended solids.

SEPARATION

The bubbles lift the solids to the surface, forming a floating foam that can be skimmed off.

Steps to Getting Started...

We offer comprehensive wastewater treatment solutions tailored to food processing and industrial facilities. From system assessments and DAF optimization to compliance support, chemical treatment programs, sludge reduction strategies, and operator training—CSI helps you stay efficient, compliant, and in control.

- 1 - Consultation

- 2 - Setup & Implementation

- 3 - Training

- 4 - Monitoring & Reporting

- 5 - Maintenance

- TAB TITLE 6

Step 1 - Expertise & Guidance in Building the Wastewater Treatment System

We help food and industrial processors design wastewater systems that are efficient, cost-effective, and built to meet today’s regulatory demands. Our team of experienced engineers, scientists, and project managers works with you to understand your plant’s unique needs, then builds a plan that fits. From selecting the right treatment

technologies to navigating complex compliance standards, we simplify the process and guide you every step of the way. You’ll get expert recommendations, practical solutions, and a system designed to perform—without the guesswork or overwhelm.

Step 2 - Setting Up the Wastewater Treatment System

Setting up a wastewater treatment system isn’t just about equipment—it’s about getting it right the first time. At CSI, we ensure a seamless installation process using proven technologies tailored to your facility’s specific needs. Our team prioritizes precision, efficiency, and long-term performance—so your system runs smoothly from day one and stays compliant for years to come.

Free Consultation

& Download Our Free Report

Implementing Processes and Procedures

Once your system is in place, we focus on fine-tuning it for real-world performance. By analyzing your specific wastewater makeup, we optimize key treatment processes—like aeration, chemical dosing, and retention times—to ensure your system runs efficiently, reduces waste, and delivers consistent, compliant results.

Step 3 - Onsite training of personnel in the processes and procedures.

A great system is only as strong as the people running it. That’s why we provide hands-on, on-site training to equip your team with the knowledge and confidence they need to operate, monitor, and maintain your wastewater treatment system effectively—day in and day out.

Free Consultation

& Download Our Free Report

Multilingual Training Support

We believe everyone deserves to understand how the system works—no matter what language they speak. That’s why our training programs are available in Spanish and other languages, making it easy for your entire team to fully engage, learn, and apply what they’ve been taught.

Free Consultation

& Download Our Free Report

Step 4 - Performance Reporting

& System Analytics

We provide detailed self-monitoring reports and real-time system analytics to help your management team stay ahead of potential issues. With accurate data and actionable insights, you can make smarter, faster decisions that keep your plant compliant and efficient.

- Annual Surcharge Statements - We provide clear, detailed annual surcharge statements to help you track wastewater-related costs and plan your budget with confidence. Our transparent reporting makes it easier to understand where your money is going—and where you can save.

- Treated Water & Effluent Monitoring - We monitor treated water and effluent quality continuously to ensure your system meets all regulatory requirements. Our strict quality controls help you stay compliant and protect the environment.

- Chemical Inventory Management - Effective treatment starts with the right materials. We manage your chemical inventory to ensure you always have the correct products in the right quantities—preventing delays, waste, or system imbalances.

- Remote Telemetry & Real-Time System Data - Access your system’s performance data anytime, anywhere. With our remote telemetry services, you get real-time insights that keep you informed, responsive, and in control—whether you're on-site or off.

Step 5 - Our Approach to Maintenance

We take a proactive, hands-on approach to maintenance—prioritizing regular inspections, preventative care, and fast response times to keep your wastewater system running efficiently and avoid costly downtime. Our goal is to catch small issues before they become big problems.

Free Consultation

& Download Our Free Report

- On-Call Servicing & Emergency Repairs - When something goes wrong, you need support—fast. Our maintenance team is on call 24/7 to provide emergency servicing and repairs, ensuring your wastewater system stays operational and efficient, no matter the hour.

- Cleaning & Flushing for Wastewater Areas and Cooling Towers - Clean systems perform better. We provide professional cleaning and flushing services for wastewater zones and cooling towers to help prevent buildup, reduce wear, and keep your operation running smoothly.

- Expert Troubleshooting and Diagnostics - When issues arise, we don’t just treat symptoms—we find the cause. Our experienced technicians specialize in pinpointing system problems and delivering precise, lasting solutions that restore performance and prevent future breakdowns.

- Grease Removal Oversight - Grease buildup can cripple system performance. We coordinate and oversee grease removal to ensure it’s done thoroughly and in full compliance with regulatory standards—protecting your equipment and your peace of mind.

- Contract Wastewater Operator Services - Need day-to-day operational support? Our licensed wastewater operators manage your system with professionalism and care, ensuring consistent performance, ongoing compliance, and fewer disruptions to your plant’s workflow.

Learn More

Your Big Blog Post Title Will Be Here

An excerpt of your post content will show up in this section so blog visitors can have an idea on what this post is about before they click it to see the post content. You can create your posts from your blog funnel dashboard.

Read More0 Views

Write a Comment

2

Read MoreYour Big Blog Post Title Will Be Here

An excerpt of your post content will show up in this section so blog visitors can have an idea on what this post is about before they click it to see the post content. You can create your posts from your blog funnel dashboard.

Read More0 Views

Write a Comment

2

Read MoreYour Big Blog Post Title Will Be Here

An excerpt of your post content will show up in this section so blog visitors can have an idea on what this post is about before they click it to see the post content. You can create your posts from your blog funnel dashboard.

Read More0 Views

Write a Comment

2

Read MoreYour Big Blog Post Title Will Be Here

An excerpt of your post content will show up in this section so blog visitors can have an idea on what this post is about before they click it to see the post content. You can create your posts from your blog funnel dashboard.

Read More0 Views

Write a Comment

2

Read More

There Are No Blog Posts To Show In The RSS Link You've Provided,

Please Try A Different Blog Posts RSS Link

Check Out Our Water Insights Hub...

Frequently Asked Questions

What types of wastewater systems do you service?

We specialize in wastewater systems used by food processing and manufacturing plants—including DAF units, anaerobic and aerobic treatment, EQ tanks, pH neutralization systems, and more. If it treats wastewater, we can help.

Do you handle compliance with local, state, and federal regulations?

Yes. Our team stays ahead of EPA, state environmental agencies, and municipal standards. We help your plant meet permit requirements and avoid fines—so your team can stay focused on production.

How do I know if my current wastewater system is underperforming?

If you're seeing frequent violations, odor issues, inconsistent discharge quality, or rising surcharge fees, your system likely needs attention. We offer on-site evaluations to identify problems fast.

Can you reduce our surcharge and hauling costs?

Absolutely. We help clients optimize treatment performance, reduce sludge volume, and improve discharge quality. That often means lower surcharges and fewer hauls—saving thousands each month.

How fast can you respond if we’re in trouble?

We move fast—especially in emergencies. If your system goes down, we’re on call to get you back in compliance and keep your plant running. We act like a true extension of your operations team.

What makes CSI different from other wastewater treatment vendors?

We don’t just sell chemicals or equipment—we deliver turnkey solutions built specifically for food processing wastewater challenges. Our experience means fewer surprises, better outcomes, and less stress for your team.

Can you train our team to operate the system more efficiently?

Yes. We offer operator training, SOP development, and coaching for your staff. Whether it’s your Water Treatment Operator, Maintenance Manager, or EHS team, we make sure everyone’s aligned and equipped.

Do you provide ongoing service or just one-time fixes?

Both. We can support emergency repairs or provide monthly service contracts that include maintenance, compliance monitoring, and system optimization. The goal: long-term peace of mind.

How do I get started with CSI?

Simple—schedule a free on-site consultation. We’ll assess your system, discuss your goals, and give you a clear plan to move forward with confidence.

REACH US

ADDRESS

2845 Pomona Blvd. Pomona, CA 91768

CONTACT

@: CSI-team@chem-serv.com

P: (800) 690-2436

OPENING HOURS

Tuesday 8:00AM-5PM

Wednesday 8:00AM-5PM

Thursday 8:00AM-5PM

Friday 8:00AM-5PM

Saturday Closed

Sunday Closed

FIND US

© 2025 CSI Environmental Corp All Rights Reserved. 141 E Badillo St, Covina, CA 91723. Contact Us. Terms of Service . Privacy Policy